Welcome, readers, to a discussion on maximizing efficiency with MRP planning tools. MRP, which stands for Material Requirements Planning, is a vital component in the manufacturing industry. By utilizing MRP planning tools, businesses can streamline their production processes, reduce lead times, and optimize inventory levels. In this article, we will explore the benefits of MRP planning tools and how they can help businesses improve their overall operations.

Overview of MRP Planning Tools

MRP (Material Requirements Planning) Planning Tools are essential for businesses that want to streamline their production processes and optimize their supply chain management. These tools help companies effectively plan and manage the materials needed for production, ensuring that there are no shortages or overstock situations. MRP Planning Tools use data from inventory levels, sales forecasts, and production schedules to create a detailed plan for purchasing and producing materials.

One of the key features of MRP Planning Tools is their ability to generate accurate demand forecasts based on historical data and current market trends. By utilizing this feature, businesses can ensure that they have the right amount of materials on hand to meet customer demand without tying up excess capital in overstocked inventory.

MRP Planning Tools also help businesses optimize their production schedules by ensuring that materials are available when needed. By aligning production with demand forecasts and inventory levels, companies can minimize lead times and reduce the risk of production delays. This not only improves efficiency but also helps businesses deliver products to customers on time.

Additionally, MRP Planning Tools offer real-time visibility into the supply chain, allowing businesses to track the movement of materials from suppliers to production facilities to customers. This visibility enables companies to quickly identify bottlenecks or delays in the supply chain and take corrective action to avoid disruptions in production.

Furthermore, MRP Planning Tools can help businesses reduce costs by optimizing inventory levels and minimizing waste. By accurately forecasting demand and aligning production schedules accordingly, companies can avoid excess inventory and reduce the risk of stockouts. This leads to lower carrying costs and higher profit margins for businesses.

In conclusion, MRP Planning Tools play a crucial role in helping businesses effectively plan and manage their materials for production. By utilizing data-driven insights and real-time visibility into the supply chain, businesses can optimize their production processes, reduce costs, and improve customer satisfaction. With the right MRP Planning Tools in place, businesses can stay competitive in today’s fast-paced market environment.

Benefits of Using MRP Planning Tools

MRP planning tools, or Material Requirements Planning tools, are essential for businesses looking to efficiently manage their inventory and production processes. The benefits of using MRP planning tools are numerous and can have a significant impact on a company’s bottom line. From improved inventory management to increased productivity, MRP planning tools offer a wide range of advantages for businesses of all sizes.

One of the key benefits of using MRP planning tools is improved inventory management. By accurately forecasting demand and automatically generating purchase orders and production schedules, MRP planning tools help businesses maintain optimal inventory levels. This not only reduces the risk of stockouts and overstocking but also minimizes carrying costs and storage expenses. With MRP planning tools, businesses can ensure that they have the right amount of inventory on hand at all times, leading to improved customer satisfaction and increased profitability.

In addition to improved inventory management, MRP planning tools also help businesses increase productivity. By streamlining the production planning process and identifying potential bottlenecks in the production schedule, MRP planning tools can help businesses minimize downtime and maximize efficiency. This allows businesses to produce goods more quickly and cost-effectively, reducing lead times and improving on-time delivery rates. With MRP planning tools, businesses can optimize their production processes and ensure that they are operating at peak efficiency.

Another benefit of using MRP planning tools is better decision-making. By providing real-time visibility into inventory levels, production schedules, and demand forecasts, MRP planning tools empower businesses to make informed decisions about resource allocation, order fulfillment, and production planning. With access to accurate and up-to-date data, businesses can quickly adapt to changing market conditions and customer demands, allowing them to stay ahead of the competition and drive business growth. MRP planning tools enable businesses to make data-driven decisions that drive efficiency and improve overall performance.

Overall, the benefits of using MRP planning tools are clear. From improved inventory management to increased productivity and better decision-making, MRP planning tools offer businesses a wide range of advantages that can help them succeed in today’s competitive marketplace. By leveraging the power of MRP planning tools, businesses can optimize their operations, reduce costs, and drive growth, ultimately leading to greater success and profitability in the long run.

Key Features of MRP Planning Tools

MRP planning tools are essential for businesses to effectively manage their production processes and inventory levels. These tools help companies streamline their operations and ensure that they have the right materials available at the right time. Below are some key features of MRP planning tools:

1. Inventory Management: One of the main features of MRP planning tools is inventory management. These tools help businesses track their inventory levels in real-time and generate reports on stock levels, reorder points, and lead times. This allows businesses to optimize their inventory levels, prevent stockouts, and reduce carrying costs.

2. Production Scheduling: MRP planning tools also offer production scheduling capabilities, which allow businesses to create detailed production schedules based on demand forecasts, lead times, and resource availability. This helps businesses ensure that they can meet customer demand while maximizing the efficiency of their production processes.

3. Material Requirement Planning: Material requirement planning (MRP) is a key feature of MRP planning tools. MRP helps businesses determine the materials and components they need to complete a production order or project. By analyzing the bill of materials, current inventory levels, and production schedules, MRP planning tools can generate accurate material requirements and ensure that businesses have the right materials available when needed.

MRP planning tools use algorithms and mathematical calculations to calculate the materials needed for production orders, taking into account lead times, order quantities, and production schedules. By automating the MRP process, businesses can reduce manual errors, streamline their production planning, and improve overall efficiency.

4. Demand Forecasting: Another important feature of MRP planning tools is demand forecasting. These tools use historical sales data, market trends, and other factors to forecast future demand for products. By accurately predicting demand, businesses can optimize their production schedules, minimize stockouts, and reduce excess inventory.

5. Reporting and Analytics: MRP planning tools also offer reporting and analytics capabilities, allowing businesses to track key performance indicators (KPIs), monitor production efficiency, and identify areas for improvement. These tools generate detailed reports on inventory levels, production schedules, material requirements, and more, helping businesses make data-driven decisions and optimize their operations.

In conclusion, MRP planning tools offer a wide range of features to help businesses optimize their production processes, manage inventory effectively, and meet customer demand. By leveraging the key features of MRP planning tools, businesses can improve efficiency, reduce costs, and enhance their overall competitiveness in the market.

Comparison of Different MRP Planning Tools

MRP (Material Requirements Planning) is an essential tool for businesses to effectively manage their inventory, production schedules, and supply chain operations. There are several MRP planning tools available in the market, each with its own unique features and capabilities. In this section, we will discuss some of the key differences between popular MRP planning tools to help you choose the one that best suits your business needs.

1. SAP ERP: SAP ERP is a comprehensive planning tool that integrates various modules for finance, human resources, and supply chain management. It offers robust MRP capabilities with real-time data visibility and forecasting functionalities. SAP ERP is suitable for large enterprises with complex manufacturing operations and global supply chains.

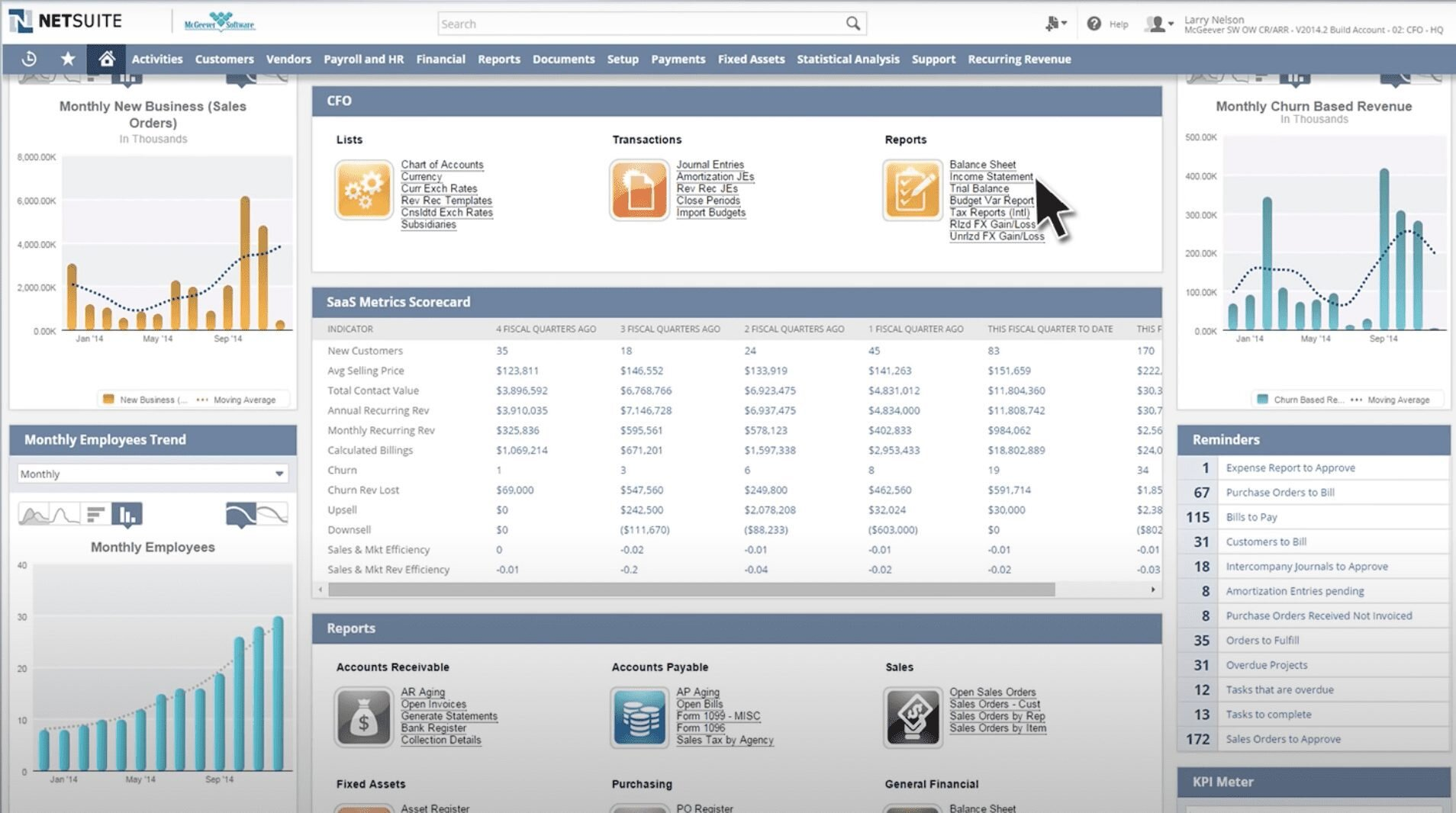

2. Oracle NetSuite: Oracle NetSuite is a cloud-based MRP planning tool that caters to small and medium-sized businesses. It offers a user-friendly interface with customizable dashboards, automated workflows, and collaboration tools. Oracle NetSuite is known for its scalability and flexibility, making it ideal for growing companies looking to streamline their production processes.

3. Microsoft Dynamics 365: Microsoft Dynamics 365 is a versatile MRP planning tool that integrates with other Microsoft applications such as Office 365 and Power BI. It offers advanced analytics, forecasting algorithms, and artificial intelligence capabilities to optimize inventory levels and production schedules. Microsoft Dynamics 365 is suitable for businesses looking to leverage Microsoft’s ecosystem for seamless integration and data-driven decision-making.

4. Fishbowl Inventory: Fishbowl Inventory is a popular MRP planning tool for small businesses and start-ups. It is known for its affordability, ease of use, and quick implementation process. Fishbowl Inventory offers basic MRP functionalities such as demand forecasting, order management, and inventory tracking. One of the key advantages of Fishbowl Inventory is its seamless integration with QuickBooks, making it a cost-effective solution for businesses looking to upgrade from manual spreadsheets to automated MRP planning.

In conclusion, the choice of MRP planning tool depends on the size of your business, industry requirements, budget constraints, and overall business objectives. By comparing the features and capabilities of different MRP planning tools such as SAP ERP, Oracle NetSuite, Microsoft Dynamics 365, and Fishbowl Inventory, you can make an informed decision to optimize your production processes and drive business growth.

Tips for Choosing the Right MRP Planning Tool

When it comes to choosing the right MRP planning tool for your business, there are several factors to consider. It’s important to carefully evaluate your company’s needs and goals to ensure that the tool you select will meet your requirements. Here are some tips to help you choose the right MRP planning tool:

1. Define your requirements: Before you start looking at MRP planning tools, make sure you have a clear understanding of your business requirements. Determine what features are essential for your operations and what functionalities you need in an MRP tool. This will help you narrow down your options and focus on tools that align with your specific needs.

2. Consider scalability: As your business grows, your MRP planning tool should be able to scale with you. Look for a tool that can accommodate an increase in production volume, changes in product lines, and other factors that may impact your business. Scalability is key to ensuring that your MRP tool remains effective in the long term.

3. Evaluate ease of use: A user-friendly interface is essential for maximizing the benefits of an MRP planning tool. Look for a tool that is easy to navigate and intuitive to use, as this will help streamline your operations and increase efficiency. Consider demos or trials of different tools to see which ones are the most user-friendly for your team.

4. Assess integration capabilities: Your MRP planning tool should be able to seamlessly integrate with your existing systems and software. This will help prevent data silos and ensure that information flows smoothly between different departments. Look for tools with strong integration capabilities to streamline your processes and improve collaboration within your organization.

5. Get feedback from users: Before making a final decision, gather feedback from potential users of the MRP planning tool. Consult with team members who will be using the tool on a daily basis to understand their needs and preferences. Their input can provide valuable insights into how different tools will impact their workflow and help you make an informed decision.

By following these tips, you can choose the right MRP planning tool for your business and set yourself up for success in managing your production processes effectively.

Originally posted 2024-09-06 15:53:58.